PRODUCTS

Dattatray Enterprises is started in 1990 as manufacturer of Lubrication System. We are first people to make manifold type Gear Pump for Lub system. ELECTROFORGE GRATING MACHINE Metallic Grating is been use in all types of industries since long time. Metallic grating is a welding process in which several flats are been use vertically on fixed distance and rods are been welded on this flat in cross on fixed distance. But manufacturing of such grating is not only difficult but time and labour consuming. This makes metallic grating costly and low profit product. But due to its strength metallic grating are been used in various types of industries like Industrial sheds, Machines, Plants, Chemical Industries, Petro-chemical- refinery –food processing plants, coal plant, cement plants, Bridges and foot-over bridges, Railways and public placeless. This has increased requirements of grating in mass quantity. Manual Gratings are not only time consuming but also do not give required quality. Electro forge process has been introduced in industries for increasing productivity and quality product. Electro forge grating machine is multi spot Fijian welding machine. This is a basically pillar type Hydraulic Press having Transformer and electrodes fixed on vertical slide. A table with ground electrode is provided bellow this slide.

Basic three types of machines are been made

(A) DOUBLE ROD WELDING MACHINE (with chain drive)

(B) DOUBLE ROD WELDING MACHINE (with dragger)

(C) SMALL ELECTROFORGE MACHINE

NORMAL MACHINE SPECIFICATION FOR ALL MODELS

1) WIDTH OF GRATING 900/1200/1500 MM

2) LENGTH OF GRATING 600/2500/6000 MM

3) FLAT BAR HEIGHT 25 TO 75 MM

4) FLAT BAR THICKNESS 2.5 TO 8 MM

5) CROSS BAR SIZES 4 TO 8 MM

6) HYDRAULIC SYSTEM 30 TO 150 TON

7) CHAIN CONVEYOR TYPE BAR FEEDING SYSTEM OR DRAGGER SYSTEM

8) WATER COLD TRANSFORMER

9) PLC BASE CONTROL PANEL

POWER ESTIMATION FOR DIFFERENT MACHINES WITH PRODUCTION CAPACITY

A) DOUBLE ROD WELDING MACHINE 900/1200/1500 KVA PRODUCTION 50 TO 80 PANEL/12 shift

B) SINGLE SPOT-WELDING MACHINE 100/250/350 KVA PRODUCTION CAPACITY 5-6 PANEL/12 hr SHIFT

OTHER MACHINES AND FACILITY REQUIRED FOR PLANT

A) SPACE MINIMUM 1000 SQM

B) TWISTING BAR MACHINE WITH CUTTING

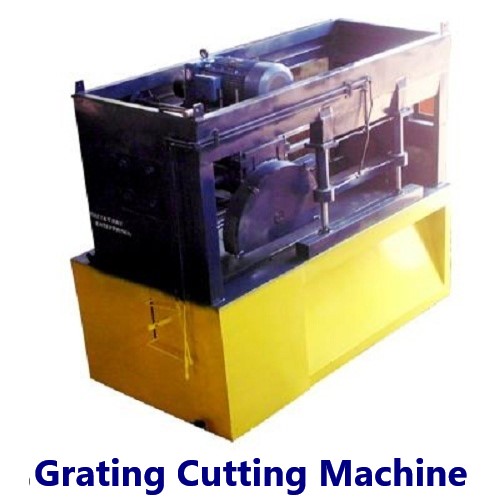

C) GRATING CUTTING MACHINES 2-3 NOS

D) CHILLING PLANT 3 TO 30 TON

E) CONVEYOR TABLES 3 – 6 NOS

F) MECHANICAL PRESS 25-50 TON 2 NOS

G) MANUAL WELDING MACHINES 2 – 12 NOS

H) LIFTING TABLE (OPTION)

I) OVER HEAD CRANES 5 TON 3- 5 NOS

J) RADIAL DRILL MACHINE 25 MM

K) BENDING MACHINE 8 FEET X 6 MM

L) SHEARING MACHINE 8 FEET X 6 MM

MANPOWER REQUIRED FOR THE PLANT

A) STAFF 4-8>

B) WORKERS 15 -50

TOTAL INVESTMENT

A) FOR DOUBLE ROD WELDING MACHINE PLANT @ 3-5 CR

B) SINGLE SPOT-WELDING MACHINE PLANT @ 0.6 TO 1.2 CORES

Dattatray enterprises is doing Manufacturing, installation and commissioning of such plants. We also under take plant installation of cable tray and automation.

Utility Demand

1) Power required 350 -1500 KVA

2) Area required 1000 sq mtr min to 2500 sq mtr

3) Chiller 36 TR

ESTIMATED PROJECT FORCAST

01) RAW MATERIAL PRICE. RS 50/ KG

02) ELECTRICAL CHARGES. RS 0.80/ KG

03) TOTAL CONVERSION COST OF MACHINE RS 6.50/ KG 04) SALE PRICE AT BLACK. RS 70/ KG

Technical Advisor Team expertise included from relevant technology having experience of highest in the industries from major three different side Metrology, machine design and resistance welding that helps DATTATRAY become a complete house of solution provided in the field of Electro forged. We are one of the most successful manufacturers in India is because of our professional team, dedicated support team members and our special approach towards the customer needs, Give us call for your requirement and we are available at your disposal.

Piru Shruti, Panse Nagar No. 1, East, Dombivli, Thane, Maharashtra - 421201, India, E mail driplub@gmail.com

All rights reserved Computer Lab @2023